You could say Dr. Camille George, associate professor in St.Thomas' School of Engineering, is leading a fruitful endeavor.

Since 2002, George has led St.Thomas' partnership with local nonprofit Compatibility Technology International, which creates "practical food and water tools that empower the global poor to better feed and support themselves," according to its website. The partnership, part of the School of Engineering's "Peace Engineering" initiative, has involved around 45 undergraduate and graduate students since it began.

George said she has since "grown to appreciate the notion of engineering solutions for the bottom billion – or the base of the pyramid. Too often we just think of engineering for Fortune 500 companies or for defense; there are many basic issues (food, water, shelter) that could be addressed by the profession."

George's 10-year collaboration with CTI has focused solely on its breadfruit tools, and last month marked her latest milestone with the nonprofit. She flew to Kauai, Hawaii, to present and build a breadfruit drier on the grounds of the National Tropical Botanical Gardens. It eventually will be on permanent display, complete with the university's logo, in the "Food for Thought" exhibit, which should open in a few years at the garden's headquarters in Kauai.

Three variations on the breadfruit drier: (front to back) the "Oldsters'" drier; the display-quality drier designed by George and Bach this summer; and the Ultralight Mod Pod.

George co-designed the drier with St.Thomas adjunct engineering professor Bob Bach. They received around 200 hours of design and logistical help from St.Thomas seniors Garrett Faust and Dan McQuillan, both mechanical engineering majors, since they began work on the redesign in late May.

The drier is a hybrid based on two driers designed earlier this year. The first was the winning design in the Peace Engineering contest − a contest George proposed and organized for St. Thomas "to gather any ideas Bob and I hadn't thought about and also to communicate to the public what we (at the School of Engineering) were doing."

The contest called on two- to three-person teams to design, build and deliver in March a breadfruit-drying device to the Breadfruit Institute, a subdivision of the NTBG, in Kauai. A School of Engineering-sponsored contest, it was judged by a panel consisting of all St.Thomas alumni who had experience working for communities in the developing world.

The winning drier was designed by retired General Mills engineer and CTI founder George Ewing, retired chemical engineer and longtime CTI member Hank Garwick, and retired physics teacher Dave Elton, who is also a longtime CTI member. The team, which dubbed itself "The Oldsters," created the simplest and least expensive of the 15 entries received, George said.

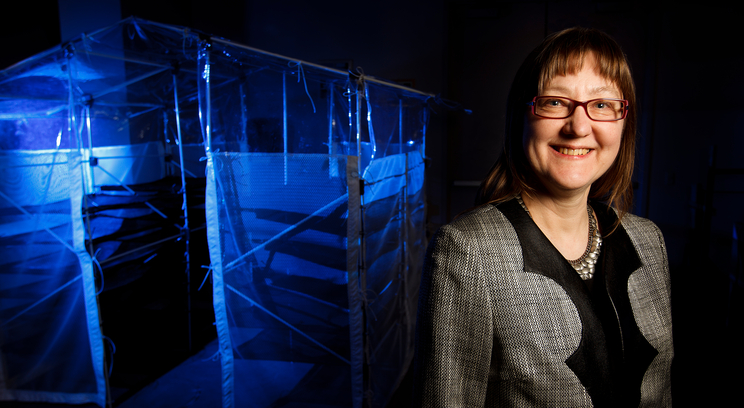

The other design used in making the hybrid was created by George and Bach, who had promised to design a drier for CTI in tandem with the contest. They christened their device the "Ultralight Mod Pod." Fully assembled, it looks like a small, simple, open-roofed house framed in fiberglass and sided with clear vinyl (pictured, with George, in the feature photo above).

"The idea behind the Ultralight," she said, "was we wanted a lightweight drier with a small footprint. Our 10-foot-by-10-foot device dries 150 square feet of breadfruit shreds, which is about 0.6 pounds per square foot of drying area, so our drier was lighter than The Oldsters' design. Bob and I took the best elements of our design (small footprint and rain protection solution) and combined them with the best elements of The Oldsters' design (low cost and structurally easy to use), and that's the hybrid we built in August. In the hybrid we wanted it to withstand tropical storms, have good rain protection, have the netting in contact with the food both food-safe and washable, and we wanted low cost."

From user comments in Haiti and Hawaii, they learned that rain and tropical storms are a common occurrence during the breadfruit harvest season, so they incorporated Lexan weatherproof panels to help it withstand tropical rain storms. George noted, "One cooperative in Jeremie, Haiti, stated that they lose one-third of their breadfruit chips to rain! Also, all the potential users I interviewed this summer wanted something robust and sturdy. That is why we incorporated a strong secure rain covering. By making the covering transparent we also increased the temperature in the top one-third of the structure by 20 degrees Fahrenheit to further facilitate the drying."

George was very happy with the redesign, which also included flexible and washable food-safe shelves that sat on very low-cost structural netting. "The collaborators in Hawaii were very pleased with the drier shelves being off the ground − they thought The Oldsters' design was too close to the ground; they have a lot of issues with feral chickens, pigs and rats," she said. "They were also very happy with the robust and waterproof construction (nothing on the drier can rust) and that the new hybrid can be put away as flat panels at the end of the season."

The hybrid drier had to be display quality and was fabricated completely with materials from Minnesota, including aluminum, Lexan and PVC tubing. This semester, Faust and McQuillan will "simplify the design, bring down the cost, and work with a fabricator in Haiti to purchase and build some of the heavier materials on site, because, George asserted, "We're not shipping the frame again!"

Faust and McQuillan will spend J-Term in Haiti doing the "heavy building" on site. The only parts they'll ship beforehand will be food-safe-netting shelves, on which the shredded breadfruit will dry. "The drier Garrett and Dan will help make this semester will further improve the quality of the product," George said.

A "field-to-fork" enterprise: from tree to flour to bakery

Dr. Camille George holds dried, shredded breadfruit. (Photo by Mike Ekern '02)

In a December 2011 Bulletin Today story promoting the drier contest, George explained that a significant challenge in taking advantage of breadfruit is its short shelf life once picked: “Drying takes out 70 percent of the water in the fruit, making the crops much easier to move and increasing their shelf life. If these designs work, it’ll be huge.”

Just a few months later, George was able to see, and take part in, the fruits of her labor.

During this fall's harvest, the NTBG will test the hybrid drier on three varieties of breadfruit. But the "bigger picture" of the drier, she said, is much more than simply the drying of breadfruit. It even extends beyond food security for Haitians.

"We're introducing social entrepreneurship from a franchise perspective," she explained. "The drier is just a small piece of the whole enterprise."

Specifically, the dried breadfruit will be ground into flour, which will fully support a new bakery, Palmaeres, in Port-au-Prince, the capital of Haiti. "With this bakery, we have shown proof of concept from field to fork!" George said.

"The idea is that we would have a ti Champion ("Little Champion") franchise, in the form of moveable kiosks (food carts)." The plans aren't yet complete, but the hope is that small-business owners would lease the kiosks with a profit-sharing business model.

Over the summer, George tested a waffle kiosk in Port-au-Prince, which was a huge success. She explained, "In the future, people will be able to take their kiosks onto the streets to make waffles, probably served with a Creole (tomato-based) sauce."

Palmaeres will be a fully operational bakery, selling ti Champion baked goods, which are mostly breadfruit-flour-based, such as rum cakes, molasses cookies and pizelles − Norwegian-style waffle cone-like cookies − in dark and light chocolate. It also will be a breadfruit flour vendor and produce 100-percent breadfruit-flour dry mix for the waffle kiosks − essentially serving as the hub for the ti Champion franchise.

"I honestly feel that the franchise idea is a wonderful idea for Haiti because it is a collective culture. People work together in family clans," George said. She noted that the average Haitian has an outdoor kitchen and that family meals are cooked over charcoal. "It's not an oven culture, and baking is not a part of the culture, so that's why the bakery as a wholesale hub makes sense. With these kiosks, you can see that it creates a ready-to-eat product for consumers to buy."

Hennepin Avenue United Methodist Church and Satag Inc., a Haiti-based organization, have assisted with the bakery's opening and also are major contributors to the Peace Engineering initiative, helping to bring food and financial security to Haiti via breadfruit.